Everyone knows the Ercol 203 armchair as the most iconic of Ercol pieces, but perhaps we should pose the question; Ercol 204 armchair – better than the Ercol 203?

Everyone loves the model 203 armchair which was manufactured from 1953 until 1983 when it was superseded by the model 204, which was made from 1983 to 1992. It is really not easy to spot the difference between the two unless you see them side-by-side. The 204 sits slightly higher than the model 203 – the seat frame is about 6cm higher at the front.

And the seat is not quite as deep on the model 204 giving a very slightly more upright sitting position. It is generally though that these changes, as they did not affect the overall aesthetics, were introduced to create a more comfortable chair, particularly given the changing shape of the population since the early 1950s. This makes sense as Ercol made similar changes to the seat of the 370 dining chair in 1987 (renaming it model 870) for the same reasons.

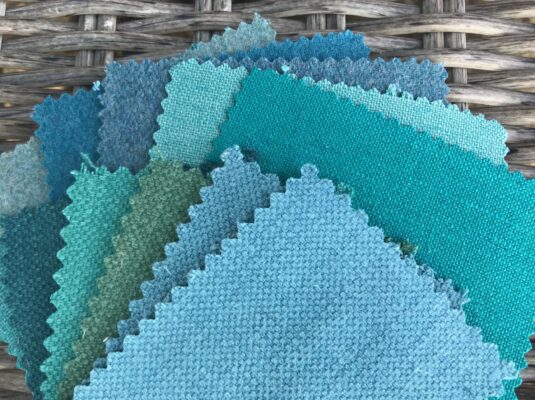

Cushions in xxx £123

Because the two models are so similar there is a tendency for “203” to become a generic name for both chairs. This can easily cause confusion, particularly as the cushion templates for each chair are different (you can’t mix and match). You will often find an Ercol 204 armchair being sold as a 203. There is also no equivalent of the 341 footstool (as far as I am aware) for the 204.

As far as comfort is concerned this will also be down to personal choice but I must say that I find the 204 by far the more comfortable of the two (although, as far as I am aware, there is no matching footstool for the 204). However there is a 204/2 two seater sofa to which all the above arguments equally apply.

Ercol 204 armchair

• Height to top of cushion at front – 43cm

• Depth of seat cushion – 62cm

• Height of back – 82 cm

• Width across arms – 70cm

• Depth of chair (from wall) – 88cm

We usually have both the Ercol 204 armchair and 204/2 sofa in stock so if you are interested, please get in touch. You will find our contact details below.

Contact Us

Please call for an appointment

Units 10 & 11

Berwick Court Farm

Alfriston Road

Alfriston, East Sussex

BN26 5QS